Next: The Alternating Current Motor

Up: Magnetic Induction

Previous: The Alternating Current Generator

Most common electrical appliances (e.g., electric light-bulbs, and electric

heating elements) work fine on AC electrical power. However, there are some

situations in which DC power is preferable. For instance, small electric

motors (e.g., those which power food mixers and vacuum cleaners) work very well on AC

electricity, but very large electric motors (e.g., those

which power subway trains) generally work much better on DC electricity. Let us

investigate how DC electricity can be generated.

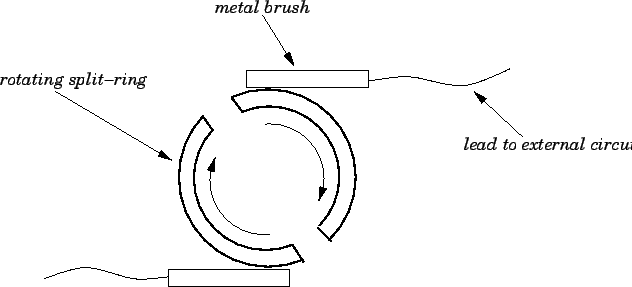

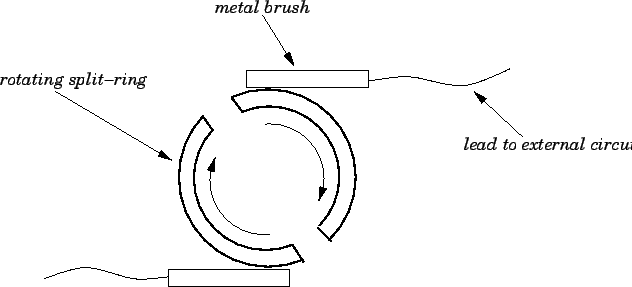

Figure 41:

A split-ring commutator.

|

A simple DC generator consists of the same basic elements as a simple

AC generator: i.e., a multi-turn coil rotating uniformly in a magnetic

field. The main difference between a DC generator and an AC generator lies

in the manner in which the rotating coil is connected to the external circuit

containing the load. In an AC generator, both ends of the coil are connected

to separate slip-rings which co-rotate with the coil, and are connected to

the external circuit via wire brushes. In this manner, the emf

seen by the external circuit is always the same as the emf

seen by the external circuit is always the same as the emf  generated around the rotating

coil. In a DC generator, the two ends of the coil are attached to different halves

of a single split-ring which co-rotates with the coil. The split-ring is connected

to

the external circuit by means of metal brushes--see Fig. 41.

This combination of a rotating split-ring and stationary metal brushes

is called a commutator. The purpose of the commutator is to ensure that

the emf

generated around the rotating

coil. In a DC generator, the two ends of the coil are attached to different halves

of a single split-ring which co-rotates with the coil. The split-ring is connected

to

the external circuit by means of metal brushes--see Fig. 41.

This combination of a rotating split-ring and stationary metal brushes

is called a commutator. The purpose of the commutator is to ensure that

the emf

seen by the external circuit

is equal to the emf

seen by the external circuit

is equal to the emf  generated around the rotating

coil for half the rotation period, but is equal to minus this emf for the

other half (since the connection between the external circuit and the rotating

coil is reversed by the commutator every half-period of rotation). The

positions of the metal brushes can be adjusted such that the connection between

the rotating coil and the external circuit reverses whenever the emf

generated around the rotating

coil for half the rotation period, but is equal to minus this emf for the

other half (since the connection between the external circuit and the rotating

coil is reversed by the commutator every half-period of rotation). The

positions of the metal brushes can be adjusted such that the connection between

the rotating coil and the external circuit reverses whenever the emf

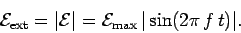

generated around the coil goes through zero. In this special case,

the emf seen in the external circuit is simply

generated around the coil goes through zero. In this special case,

the emf seen in the external circuit is simply

|

(218) |

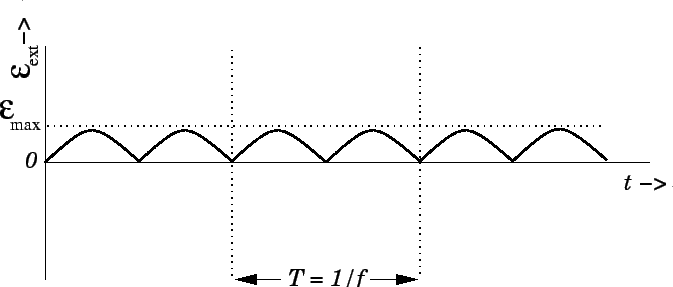

Figure 42 shows

plotted as a function of

time, according to the above formula. The variation of the emf with time is

very similar to that of an AC generator, except that whenever the AC generator

would produce a negative emf the commutator in the DC generator reverses

the polarity of the coil with respect to the external circuit, so that the negative

half of the AC signal is reversed and made positive. The result is a bumpy

direct emf which rises and falls but never changes direction. This type of

pulsating emf can be smoothed out by using more than one coil rotating about the

same axis, or by other electrical techniques, to give a good imitation of the

direct current delivered by a battery. The alternator in a car

(i.e., the DC generator which recharges the battery) is a common example

of a DC generator

of the type discussed above. Of course, in an alternator, the external torque needed to rotate

the coil is provided by the engine of the car.

plotted as a function of

time, according to the above formula. The variation of the emf with time is

very similar to that of an AC generator, except that whenever the AC generator

would produce a negative emf the commutator in the DC generator reverses

the polarity of the coil with respect to the external circuit, so that the negative

half of the AC signal is reversed and made positive. The result is a bumpy

direct emf which rises and falls but never changes direction. This type of

pulsating emf can be smoothed out by using more than one coil rotating about the

same axis, or by other electrical techniques, to give a good imitation of the

direct current delivered by a battery. The alternator in a car

(i.e., the DC generator which recharges the battery) is a common example

of a DC generator

of the type discussed above. Of course, in an alternator, the external torque needed to rotate

the coil is provided by the engine of the car.

Figure 42:

Emf generated in a steadily rotating DC

generator.

|

Next: The Alternating Current Motor

Up: Magnetic Induction

Previous: The Alternating Current Generator

Richard Fitzpatrick

2007-07-14

![]() seen by the external circuit is always the same as the emf

seen by the external circuit is always the same as the emf ![]() generated around the rotating

coil. In a DC generator, the two ends of the coil are attached to different halves

of a single split-ring which co-rotates with the coil. The split-ring is connected

to

the external circuit by means of metal brushes--see Fig. 41.

This combination of a rotating split-ring and stationary metal brushes

is called a commutator. The purpose of the commutator is to ensure that

the emf

generated around the rotating

coil. In a DC generator, the two ends of the coil are attached to different halves

of a single split-ring which co-rotates with the coil. The split-ring is connected

to

the external circuit by means of metal brushes--see Fig. 41.

This combination of a rotating split-ring and stationary metal brushes

is called a commutator. The purpose of the commutator is to ensure that

the emf

![]() seen by the external circuit

is equal to the emf

seen by the external circuit

is equal to the emf ![]() generated around the rotating

coil for half the rotation period, but is equal to minus this emf for the

other half (since the connection between the external circuit and the rotating

coil is reversed by the commutator every half-period of rotation). The

positions of the metal brushes can be adjusted such that the connection between

the rotating coil and the external circuit reverses whenever the emf

generated around the rotating

coil for half the rotation period, but is equal to minus this emf for the

other half (since the connection between the external circuit and the rotating

coil is reversed by the commutator every half-period of rotation). The

positions of the metal brushes can be adjusted such that the connection between

the rotating coil and the external circuit reverses whenever the emf

![]() generated around the coil goes through zero. In this special case,

the emf seen in the external circuit is simply

generated around the coil goes through zero. In this special case,

the emf seen in the external circuit is simply